Finding the Perfect Optocoupler for Industrial Applications

You must pick the right optocoupler for your system. This helps keep things safe and working well. Every job needs special features. You should check the optocoupler’s isolation voltage, speed, and reliability. Make sure these match what you need. New devices like hcpl0600 work fast and are strong. But using them for a long time in tough places can hurt how they work. For example, LED output can get weaker faster. Plastic housing may not work as well after a while. If you follow The selection rules for optocouplers HCPL0600R2, you make your system safer. You also lower risks and make things more reliable.

Key Takeaways

Pick an optocoupler with high isolation voltage. This keeps your team and equipment safe from dangerous currents. Choose an optocoupler with the right speed for your job. This helps you avoid delays and keeps data transfer correct. Look at the Current Transfer Ratio (CTR) in the datasheet. Make sure it fits your circuit’s needs for good performance. Think about things like temperature and electrical noise. This helps the optocoupler last longer in hard conditions. Always check the datasheet for details and safety certifications. This helps you make smart choices for your system.

Key Factors for Selecting Optocoupler

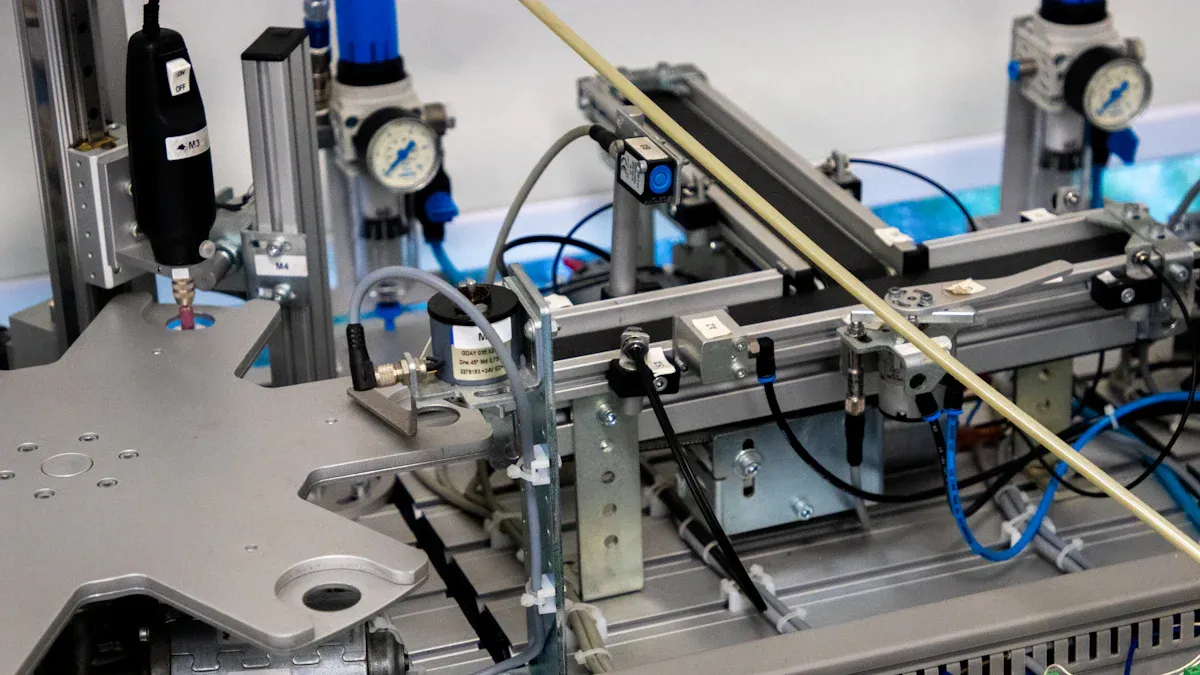

When you pick an optocoupler for factories, you need to check some important things. These things help you make safe and strong systems. The HCPL0600 from onsemi is a good choice. It is fast and works well for a long time. Let’s talk about each thing you should check.

Isolation Voltage

Isolation voltage is very important. It shows how much voltage the optocoupler can block. In factories, high voltage can break machines or hurt people. Isolation voltage stops dangerous currents from crossing over. You should pick an optocoupler with a higher isolation voltage than your system’s highest voltage. This keeps your team and equipment safe.

Tip: Always look at the datasheet for isolation voltage. Make sure it is enough for your needs.

Bandwidth and Speed

Bandwidth and speed tell you how fast the optocoupler sends signals. Many uses, like motor control or data transfer, need quick signals. The HCPL0600 can send data up to 10 Mbit/s. This makes it good for fast jobs. If you use I2C or fast digital signals, you need a fast optocoupler. Slow ones can cause mistakes or delays.

For I2C fast mode (400 kHz), delay should be under 0.6 ms.

Fast optocouplers work for data from 100 kilobit/s to 50 megabit/s.

Current Transfer Ratio

Current Transfer Ratio (CTR) shows how well the optocoupler moves current. If CTR is too low, your circuit may not work. If it is too high, you might spend too much money. CTR can change with heat, LED current, and age. Check the CTR in the datasheet and make sure it fits your job.

Description | |

|---|---|

Current Transfer Ratio | Shows how well the optocoupler moves current from input to output. |

Input/Output Voltage | Makes sure the device can handle your system’s voltage levels. |

Response Time | Tells you how fast the optocoupler reacts to input changes. |

Isolation Voltage | Keeps input and output safely separated. |

Cost | Affects your project budget. |

Availability | Makes sure you can get the part when you need it. |

Reliability | Ensures the optocoupler works well for a long time in tough environments. |

Power and Thermal Management

Power and heat can change how long your optocoupler lasts. Fast devices can get hot. You need to keep them cool so they do not break. Use heat sinks or fans if needed. The HCPL0600 has special packaging to help with heat. Always check power ratings in the datasheet. Make sure your design does not let the device get too hot.

Note: Good cooling helps your optocoupler last longer and work better in factories.

Reliability in Harsh Environments

Factories can be hot, cold, or wet. Some places have lots of electrical noise. Your optocoupler must work well in these hard places. The HCPL0600 works from -40°C to +85°C, so it fits many tough jobs. Pick devices with strong noise protection and good quality checks. This helps stop problems in jobs like motor drives or power supplies.

Very hot or wet places can lower how well it works.

Always check if the optocoupler meets safety rules, like UL or VDE.

If you focus on these key things, you can pick the right optocoupler for your job. Always read the datasheet and think about what your system needs. This helps you avoid problems and build safe, strong equipment.

Optocoupler Basics for Industrial Use

How Optocouplers Work

You might ask how an optocoupler keeps machines safe. Optocouplers use a simple process to work. When you send current to the LED, it glows with infrared light. The photodetector sits near the LED and catches this light. It turns the light into an electrical signal for the output. This keeps the input and output circuits apart.

You turn on the LED inside the optocoupler.

The LED gives off infrared light.

The photodetector catches the light and makes a new signal.

Tip: This way gives strong signal isolation. Your control circuits stay safe from high voltages.

Optocouplers keep circuits separate from each other. You can use them to make your control system steady. They are important when you need safe links between low-power controls and big machines.

Industrial Safety and Signal Integrity

Factories need systems that are safe and work well. Optocouplers protect electronics from high voltages and surges. They stop ground loops, which can cause bad currents and mess up signals. You get better signal integrity because optocouplers keep signals clear. This matters for good measurements and controls.

Electrical isolation keeps your equipment safe from high voltages.

Ground loop removal stops signal trouble.

Better signal integrity keeps your data right.

Noise immunity protects signals from interference in loud places.

Improved safety keeps you and machines safe from accidents.

Note: Using optocouplers helps you meet safety rules and keeps your system working well.

Optocouplers work in hard places. You can trust them to keep signals clean and your team safe. If you want strong industrial systems, start with good signal isolation and reliable optocouplers.

Guide for Selecting Optocouplers HCPL0600R2

Application Requirements

First, you need to know what your system does. Think about where it will be used. Some machines need quick signals. Others need to be safe from high voltage. The The steps for selecting optocouplers HCPL0600R2 help you pick the right optocoupler. For example, motor controls and power supplies need fast and robust devices. The HCPL0600 works well in noisy and fluctuating temperatures. It fits many jobs in factories.

Tip: Write down your system’s voltage, speed, and temperature needs before you choose an optocoupler.

Matching Specifications

You have to check the specs to see if the optocoupler fits your job. The 光电耦合器的选型 hcpl0600r2 method uses a table to compare features. Here is an easy way to look at the specs:

Specification | Description |

|---|---|

Rise Time/Fall Time | Shows how quickly the output switches, which affects speed. |

Propagation Delay Time | Tells you how long it takes for the signal to move from input to output. |

Shows how much voltage the optocoupler can block for safety. | |

Operating Ambient Temperature | Tells you the temperature range for reliable operation. |

LED Specifications | Includes LED current and efficiency, which affect performance. |

You should always match these specs to your system. The HCPL0600 gives high isolation voltage and quick response. This makes it a good pick for many factory uses.

Understanding Datasheets

You need to read the datasheet with care. The The method for selecting optocouplers HCPL0600R2 means you look for numbers like isolation voltage, CTR, and speed. You also check how to set up the circuit. Always use current limiting resistors to keep the LED safe. Voltage protection helps the device handle spikes. The HCPL0600 datasheet shows how to connect the device and what values to use. If you follow this guide, you will avoid mistakes and keep your system safe.

⚡ Always use the datasheet as your main reference. Good planning and protection help your optocoupler last longer.

Types of Optocoupler

There are many types of optocouplers in factories. Each type is good for certain jobs. Knowing the differences helps you pick the right one.

Phototransistor

Phototransistor optocouplers use a transistor that reacts to light. The transistor makes the signal stronger. These work best in DC circuits. They are slower than other types. But they give bigger output currents. Use them when speed is not important.

Slower to react

Best for DC circuits

More sensitive to signals

Phototransistor optocouplers are good when you need strong signals but not fast ones.

Photodiode

Photodiode optocouplers work much faster. You can use them for fiber optic links and fast signals. They do not make the current bigger like phototransistors. But they switch on and off very quickly. These are best for quick data jobs.

Fast to react

Used for high-speed jobs

Lower output current

If your system needs to be fast, photodiode optocouplers are a good pick.

Photovoltaic

Photovoltaic optocouplers make voltage when light hits the photodiode. You use them to turn on MOSFET gates or other switches. They do not need extra power for the output side. These are good for switching and control jobs that need isolation.

Makes voltage at the output

Good for turning on switches

No extra power needed for output

High-Speed Logic Gate

High-speed logic gate optocouplers, like the HCPL0600, send data very fast. They also keep circuits safe from noise and surges. You use them in digital systems. They help keep your signals clear and safe.

Performance Benefit | Description |

|---|---|

High Data Transfer Rates | Sends digital data fast and reliably |

Electrical Isolation | Keeps sensitive electronics safe from noise and surges |

Enhanced Signal Integrity | Stops data from getting messed up by interference |

High-speed logic gate optocouplers are great for sending data in modern factories.

Specialized for Harsh Conditions

Some optocouplers are made for tough places. You need these if your system gets very hot, cold, or noisy. These types work in wide temperature ranges and block high voltages. They keep working even when there is lots of electrical noise.

Feature | Description |

|---|---|

Works from -40°C to 125°C or even higher | |

Isolation Voltage | Keeps circuits safe when voltage is high |

Durability Against Transients | Keeps working during electrical noise and surges |

Pick special optocouplers if your system works in hard places.

Different optocouplers are best for different jobs. When you know what your system needs, you can choose the best type for safety and performance.

Selecting the Right Optocoupler: Step-by-Step

Picking the best optocoupler can seem tough. You can make it simple by using a clear plan. This guide helps you choose what fits your needs. It works for microcontrollers or big factory systems.

Define Application Needs

First, write down what your system should do. Think about where you will use the optocoupler. Is it for microcontroller i/o isolation? Do you need to keep a microcontroller safe from high voltages? Make a list of main jobs. You might need to send quick signals, block high voltages, or work in hot places. Knowing these needs helps you avoid problems.

Tip: Ask yourself these questions:

What voltage do you need to keep apart?

How fast does your signal need to go?

Will you use it with a microcontroller?

Is there lots of electrical noise in your area?

What is the temperature where you work?

Compare Key Specifications

You need to look at the main features of each optocoupler. Check the datasheet for every device. The table below shows what to look for:

Specification | Description |

|---|---|

Voltage Ratings | Isolation voltage keeps your system safe. |

Current Transfer Ratio (CTR) | Pick a value that matches your output. |

Switching Speed | Fast optocouplers are best for digital signals. |

Type of Load | For AC loads, use the right type, like photo-triac. |

Package and Standards | Look for UL or IEC safety certifications. |

If you use a microcontroller, pick an optocoupler with fast switching speed. This lets your microcontroller send and get signals quickly. The onsemi HCPL0600 is good for microcontroller i/o isolation. It sends data fast and keeps circuits safe.

Review Manufacturer Data

Always check the manufacturer’s data. It shows if the optocoupler fits your job. The table below tells you what to check:

Key Factors | Description |

|---|---|

Growth Drivers | Electric cars, factory robots, and internet use more optocouplers. |

Applications | Used in motor control, power supplies, data links, and digital logic. |

Market Segment | Factories use many optocouplers for different jobs. |

The onsemi HCPL0600 is special because it has UL recognition and VDE approval coming soon. These safety marks mean it follows strict rules. You can trust it for jobs needing fast data and strong isolation, like microcontroller i/o isolation or motor control.

Reliability and Support Checklist

Before you finish, use this checklist. It helps you make sure you did not miss anything:

Does the optocoupler meet your voltage and speed needs?

Is it certified by UL or VDE for safety?

Can it work in your system’s temperature range?

Does it fit your microcontroller’s input and output levels?

Is the datasheet easy to read?

Can you get help from the manufacturer?

Will it last a long time in your work area?

✅ If you check all these boxes, you are close to picking the right optocoupler for your project.

The onsemi HCPL0600 gives you fast speed, strong isolation, and trusted safety marks. You can use it with microcontrollers, power supplies, and motor controls. Always follow these steps to make smart choices for your factory systems.

Common Mistakes in Optocoupler Selection

When you pick an optocoupler, you should avoid some mistakes. These mistakes can make your system unsafe or not work right. Let’s see what people do wrong and how you can stop these problems.

Ignoring Isolation Needs

You always need to check your system’s isolation needs. If you skip this, people and machines can get hurt. Dangerous voltages might move into low-voltage parts. This can hurt workers and break important parts. Without good isolation, electrical noise can get in. This noise can mess up your signals.

Tip: Always pick an optocoupler with enough isolation voltage. An isolation barrier keeps people and equipment safe.

An isolation barrier stops dangerous voltages from crossing.

Good isolation keeps signals clear and blocks noise.

If you ignore isolation, you risk safety and system problems.

Overlooking Environmental Factors

Factories can be hot, cold, or noisy. If you do not check the environment, your optocoupler might not last long. Some devices only work in certain temperatures. Others can break if they get wet or dusty. You need to match the optocoupler’s ratings to your work area.

Check the temperature range in the datasheet.

Make sure the device can handle electrical noise.

Pick optocouplers with strong cases for tough places.

Misjudging Speed Requirements

Speed is important for many factory jobs. If you use a slow optocoupler for fast signals, your system may not work. Delays can cause mistakes in data or controls. Always check the switching speed and data rate.

Mistake | Description |

|---|---|

Using an optocoupler to drive a load above its rating (≤50mA) instead of a relay or SSR. |

Never guess the current. Always check or measure it.

Use fast optocouplers for quick signals, like the HCPL0600.

If you avoid these mistakes, your system will be safer and work better. Always read the datasheet and make sure the optocoupler fits your real needs.

You can find the right optocoupler for your project by following a few clear steps. Start by listing your needs. Check the datasheet for important details. Use the checklist to make sure you do not miss anything. Choose certified products like the HCPL0600 for safety.

Remember, understanding each optocoupler’s features helps you build strong and safe systems.

FAQ

What is the main job of an optocoupler in industrial systems?

An optocoupler keeps control circuits safe from high voltages. It lets signals go through but blocks dangerous currents. This protects people and equipment from harm.

How do you know if the HCPL0600 fits your application?

Look at your system’s voltage, speed, and temperature needs. Check these against the HCPL0600 datasheet. If they match, you can use it without worry.

Why should you care about certifications like UL or VDE?

Certifications mean the optocoupler follows strict safety rules. Certified devices work safely in tough places. This helps you meet important industry standards.

Can you use the HCPL0600 with microcontrollers?

Yes, you can use it with microcontrollers. The HCPL0600 gives fast speed and strong isolation. It is a good pick for digital systems.

See Also

Selecting The Ideal LCD Key For Your Vehicle

Finding A Trustworthy Auto Locksmith For Your Vehicle

iSun's Recommendations For Choosing Key Programming Services

iSun Digitech Limited

Contact : Coco Huang

E-mail: sales@iasun.cn